TEL

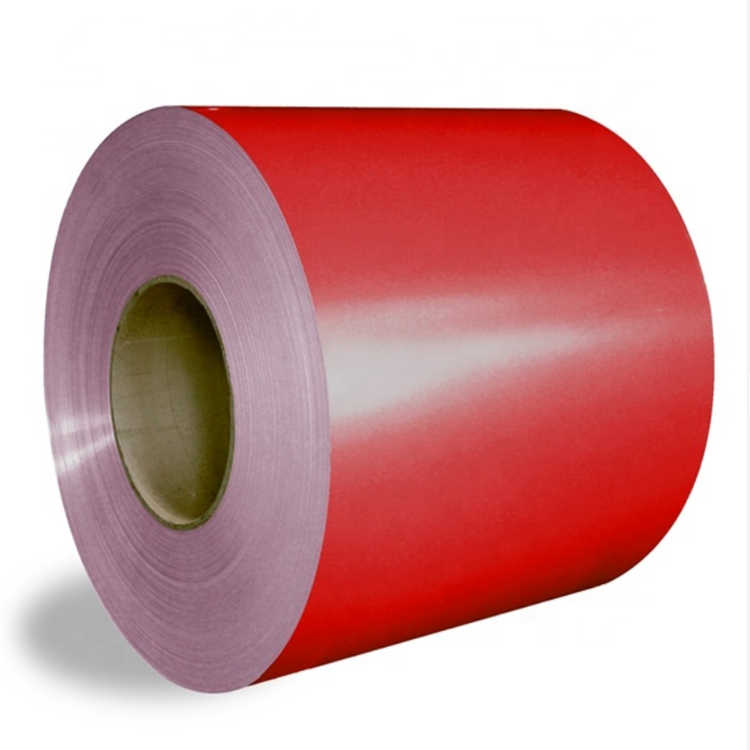

Color Aluminum Sheet/Coil

width:600-2600mm,thickness:0.3mm-60mm

1000,2000,3000,4000,5000,6000,7000 series

30% T/T deposit,70% T/T or 70% L/C at sight balance

| Product | Aluminum Color Coated Sheet/Coil |

| Property | Anti-Corrosion,Heat Resistant |

| Surface | Color Coated Coil |

| Production Process | Cold Rolled,Hot Rolled |

| Internal Diameter | 300mm,405mm,505mm or per request |

| Temper | O,H14,H24,H32,H112 Etc;T4,T651 Etc |

| Thickness | aluminum sheet:0.15mm--6.0mm; aluminum plate:6.0mm--25.0mm; As Your Request Aluminum Coil |

| Coil Weight | 2-4 tons |

| MOQ | 7 tons(According to specifications) |

| Payment Term | TT,LC,WestUnion |

| Package | Export wooden pallets,craft paper,anti-blushing agent. |

| Delivery Time | 15-20days |

| Surface treatment | mill finish, sandblasting, anodizing, electrophoresis, polishing, power coating |

| Surface | Mill, Bright,Polished,Hairline, Embossed,etching |

| Application | Construction ,Building,Decoration ,Curtain Wall,Roofing,Mould,Lighting,curtain wall, ship building,Aircraft,Oil Tank ,Truck Body,etc. |

Colored aluminum refers to the coloring treatment of the surface of aluminum alloy. Because the performance of aluminum alloy is very stable, it is not easy to be corroded. Generally, the surface layer can be guaranteed not to fade for at least 30 years after special treatment. It is also because of its low density, high hardness, and unit volume. The weight is the lightest among metal materials.

Color aluminum is a new type of material that has recently emerged in the field of doors and windows. Compared with plastic steel, its biggest advantage is that it is incomparable in strength, and its color is changeable, and it will never face the "toxic" that plastic steel is always questioned. word.

Uniform color, bright and clean, strong adhesion, sturdiness and durability, acid and alkali resistance, weathering resistance, decay resistance, friction resistance, ultraviolet radiation resistance, and strong weather resistance.

1. The surface of the color aluminum plate is flat, and there is no composite high temperature indentation on the surface. There is no residual stress on the board surface and no deformation after shearing.

2. The color-coated aluminum sheet has good mechanical properties, light weight, high strength, and quick and convenient installation and construction. Use high-quality aluminum, plastics and adhesives, and use advanced composite technology. The product has the required bending and flexural strength for decorative panels, and changes in wind pressure, temperature, humidity and other factors in the four seasons of the climate will not cause bending, deformation, expansion, etc.

3. The color-coated aluminum sheet should have good weather resistance, and the paint pattern formed by connecting coating and high-temperature baking, high gloss retention, good color temperature, and many colors, can meet the various color requirements of modern buildings, and color difference The change is minimal. Polyester paint is guaranteed for 10 years, and fluoroester paint is guaranteed for more than 20 years.

4. Color-coated aluminum sheets need to be environmentally friendly and safe. The main component of fluorocarbon polymer coatings is Kynar500 fluorocarbon resin. This fluorocarbon resin has durable binding force and the most stable molecular structure, which determines the fluorocarbon spray treatment The products can resist wind, rain, industrial waste gas, acid rain and other erosions for a long time, and can withstand harsh weather conditions without discoloration, fading, peeling, cracking, pulverization, etc., and the service life exceeds 20 years. Strong low pollution, it is difficult to attach pollutants on the surface, can maintain a long-term smoothness, easy to maintain and clean, does not release any toxic gas, does not cause corrosion of the keel and fixed parts, and is flame retardant.

5. The color-coated aluminum sheet is excellent in decoration and has many shapes. The coating color can be customized according to the needs of customers, giving customers a wide range of individual choices, which can enrich the humanistic connotation of the product and give people more beautiful enjoyment.

Used for Doors and windows, sun rooms, balcony encapsulation and other fields of high-end real estate are widely used. Color-coated aluminum coil has become one of the most popular top-level decorative materials. It is a kind of green with environmental protection, durability and aesthetic characteristics.

Common Package:

Waterproof Kraft Paper + Wooden Pallet (each 3 tons) + Bundle with steel strip.

Or Package can also according to your requirements.

The time of delivery:

Within 7-10 days after receipt of advance payment